Large Format Printers and Solutions

- All products

- Special Offers127 products

- Art & Craft Nook261 products

- Accessories0 products

- Copic200 products

- Die0 products

- DIY Kit0 products

- DIY Machines0 products

- Marabu0 products

- Fabric & Silk Paints0 products

- Liners & Accessories0 products

- Marabu Accessories0 products

- Marabu Acryl Color0 products

- Marabu Aqua Pen0 products

- Marabu Art Crayon0 products

- Marabu Art Spray0 products

- Marabu Artist Acryl0 products

- Marabu Chalky Chic0 products

- Marabu Fino0 products

- Marabu Forte0 products

- Marabu Graphix0 products

- Marabu Kids0 products

- Marabu Mixed Media0 products

- Marabu Neon0 products

- Marabu Paint Sets0 products

- Marabu Robust0 products

- Marabu Textil Paint0 products

- Marabu Universal0 products

- Porcelain & Glass Painter0 products

- Martha Stewart0 products

- Mod Podge61 products

- Daler Rowney92 products

- Folk Art86 products

- Large Format Printers and Solutions63 products

- Office Automation37 products

- Office Essentials210 products

- Plaid65 products

- Silhouette29 products

- Transotype24 products

Showing all 21 results

KALA Arkane 1650

The Kala Arkane 1650 is a high volume cold laminator with heat assisted top roller which warms the lamination film to 140°C to improve polymerization. Ideal for single sided lamination with or without backing paper, encapsulation and mounting, this piece of hardware produces 1650mm (65 inch) laminations, can mount on to boards up to 50mm (2 inches) and offers an adjustable speed of up to 6.20m/min.

KALA Atlantic 1650

The Atlantic 1650 offers single-sided lamination, simultaneous lamination, adhesive mounting, encapsulation and board mounting of thicknesses up to 50mm. It’s one of the most versatile laminators on the market, proving hot and cold control over your finishing requirements. This high volume, fully adjustable hot and cold laminator comes with independent heat settings for its top and bottom rollers of up to 140ºC.

KALA Mistral 2100

The Kala Mistral 2100 85" Laminator offer single-sided lamination, simultaneous lamination and adhesive mounting, encapsulation and board mounting up to 50mm (2") thick. The Mistral laminators are high-volume machines with heat assisted top rollers from 30-60°C. The 2100 easily accommodates 2m wide material so is the perfect solution for the high volume user with frequent demands for finishing up to 2m wide.

KALA Atlantic 1080

This Kala Atlantic laminator is for high volume, full hot and cold machines up to 140°C and provides the ideal solution for production environments that require the flexibility for full hot and cold control over their finishing requirements. It offers single-sided lamination, simultaneous lamination and adhesive mounting, encapsulation and board mounting up to 25mm (1").

Summa F1612

The Summa F1612 is a completely new cutting product based on expertise gained from over a quarter century of building the world's finest cutting plotters. The advanced engineered flatbed cutting table is designed for cutting sheet and rigid materials, as well as roll stock. Up to three tools can be inserted at one time into the multi-module tool holder. Changing tools is quick and easy due to the innovative single-screw fastening system. Automatic tool recognition, combined with digital and mechanical depth and pressure control, ensures precise cutting on a vast array of materials.

Summa F 1832

The Summa F1832 is largely based on the proven technology of Summa’s F Series flatbed systems. Unsurpassed cutting quality, utmost durability and maximum tool modularity within a user-friendly working operation are only a few of the key features of the renowned Summa F Series, all of which can be found in the F1832. With this new size Summa plans to further develop its business in different innovation markets.

Summa F3220

Summa’s professional Flatbed System is an innovative solution for producing a broad variety of signage, displays, samples, packaging applications, and more. With an ever-increasing arsenal of tools and optional add-ons, this is the breakthrough cutting solution you’ve been dreaming about.

The F3220 F Series flatbed cutter has a working width of 3.2 m. It is the ideal companion to process wide-format materials with utmost ease and accuracy. Thanks to the size users are able to obtain a print & cut workflow fitting seamlessly into each other, opening up to endless applications for the textile market in particular.

Summa F3232

Summa’s professional Flatbed Cutting System is an innovative solution for producing a broad variety of signage, displays, samples, packaging applications, and more. With an ever-increasing arsenal of tools and optional add-ons, this is the breakthrough cutting solution you’ve been dreaming about.

The F3232 is Summa’s large-format F Series flatbed cutter, the ideal companion to process popular print sizes with utmost ease and accuracy. The large working area enables a print & cut workflow fitting seamlessly into each other, opening up to endless applications for sign & display and the textile market.

SISER TS ONE

TS ONE is the manual heat press model from unique and patented design, which allows you to apply to any fabric with our transfer materials in a simple and reliable way. The side opening of the upper arm and the large work space between the support structure and the plates allow to operate quickly and in total safety. The heat press has a digital display that indicates the temperature and an audible alarm that alerts the user to the end of the transfer time. The pressure is adjustable manually. The top plate and bottom are both adjustable.

SISER SWING AND PULL

The Siser Swing & Pull is the new transfer press from Siser. The heating plate swings to the side and the worktop slides forward. This enables even better loading of the textiles. It is ideal for textile transfers on T-shirts, sweatshirts, etc. With a working area of 38 x 50 cm, you can print all common formats quickly and professionally. The TS One is supplemented by various replacement plates and modules.

SISER TS MONO

TS MONO is an automatic heat transfer press providing a pneumatic function and a single supporting plate, suitable for all kinds of applications on textiles (thermotransfer materials, plastisol, sublimatic). The upper plate opens automatically swivelling to the side ensuring operating safety. Its versatility allows the operator to print on objects with a maximum thickness of 50 mm (aluminium, ceramics…) Printing plates (15 x 15 cm or 15 x 38 cm) and cap sets are optional and available at extra cost.

SISER TS DUO

The TS DUO from Siser is an automatic heat transfer press with a pneumatic function and a double supporting plate, suitable for all kinds of applications on textiles (thermotransfer materials, plastisol, sublimatic). The upper plate opens automatically swivelling to the side ensuring operating safety. Its versatility allows the operator to print on objects with a maximum thickness of 50 mm (aluminium, ceramics…)Additional printing plates (15 x 15 cm or 15 x 38 cm) and cap sets are optional extra's.

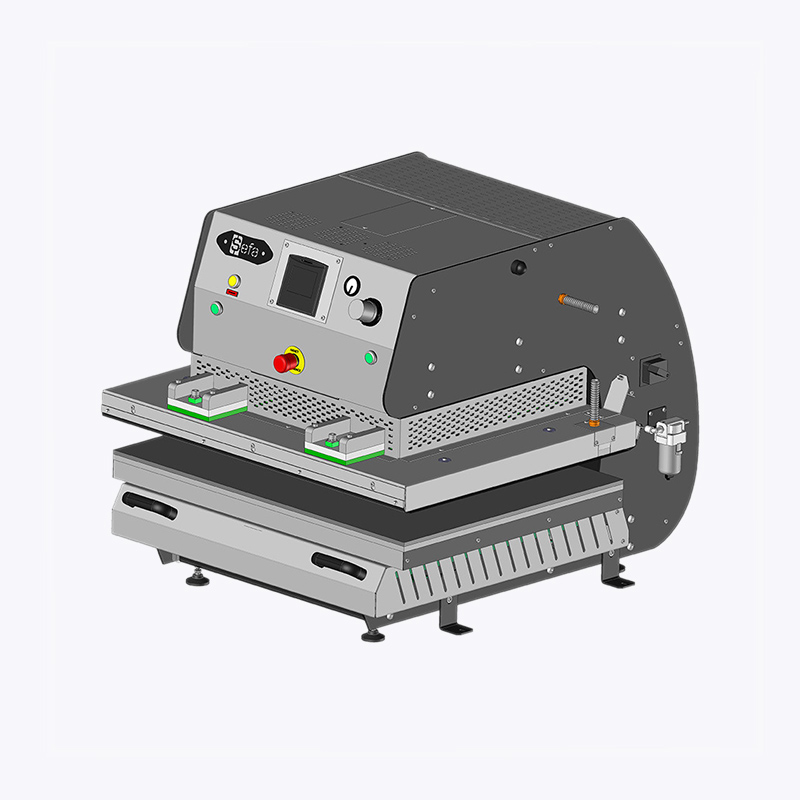

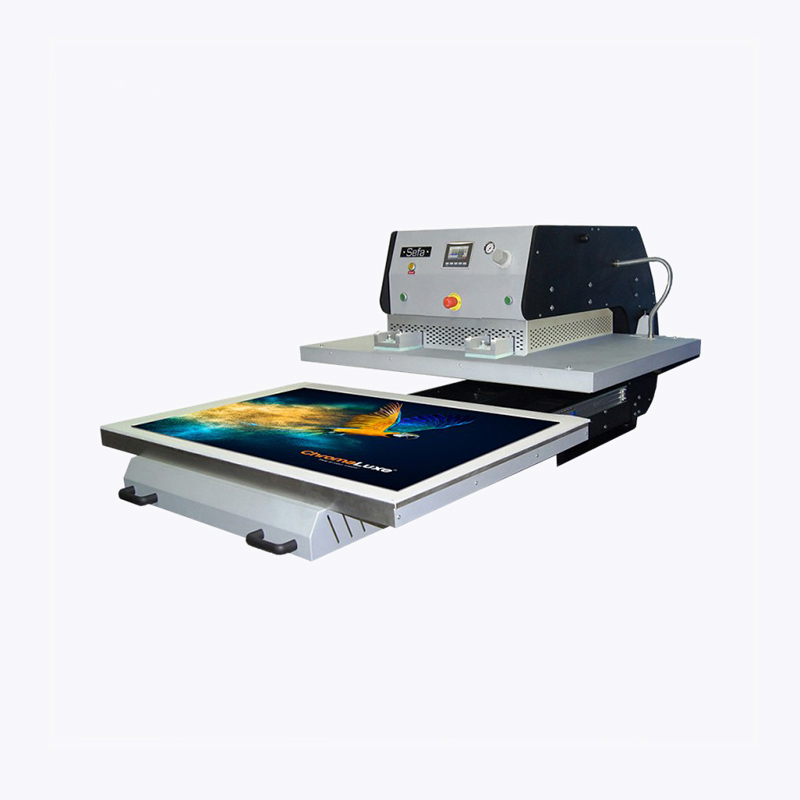

SEFA SLIDE 1285

The SLIDE 1285 was created in partnership with ChromaLuxe, the world-leading manufacturer of high-quality, rigid sublimation substrates. The SLIDE 1285’s two independent heating areas give you the power to sublimate very high-definition images up to 120 x 80 cm onto a range of substrates, including textiles, aluminium, MDF, wood, tiles, etc. Suitable for: large-format textile prints, sublimation on large-format textiles and large-format rigid substrates.

SEFA SUBLIMAX 1510

The SUBLI 1510 was created in partnership with ChromaLuxe, the world-leading manufacturer of high-quality, rigid sublimation substrates. Large format pneumatic press with two motorized drawer plates dedicated to textile and rigid substrate sublimation. Its two independent heating zones, the SULI 1510 allows to sublimate very high definition images up to 150 x 100cm on various supports: textile, aluminium, MDF, wood, tiles. Suitable for: large-format textile prints, sublimation on large-format textiles and large-format rigid substrates.

SEFA SUBLIMAX 2513

The SUBLIMAXI 2513 is our largest press model. The SUBLIMAXI 2513 was created in partnership with ChromaLuxe, the world-leading manufacturer of high-quality, rigid sublimation substrates. Suitable for: large-format textile prints, sublimation on large-format textiles and large-format rigid substrates.